HPCS 101

High Pressure Coolant Systems 101

Since the advent of manual and numerically controlled machines, engineers and machine operators have been trying to reduce machine cycle times and improve efficiency. Advancements in machine capabilities and cutting tool technology have steadily improved machining processes.

Coolant

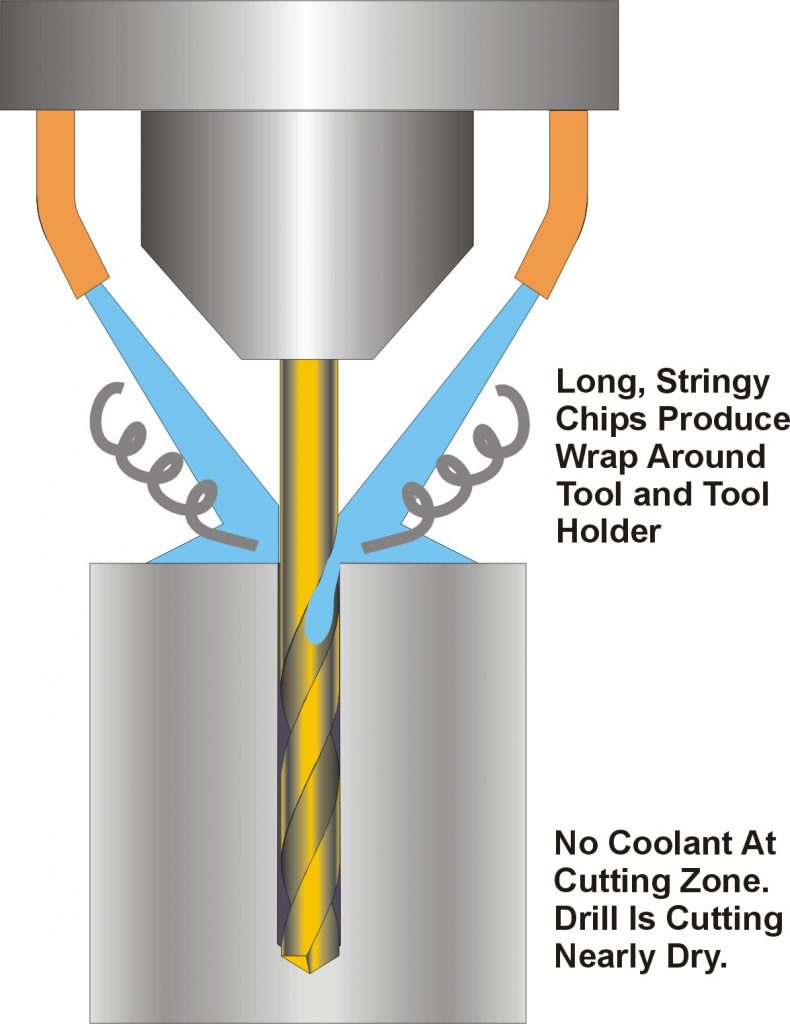

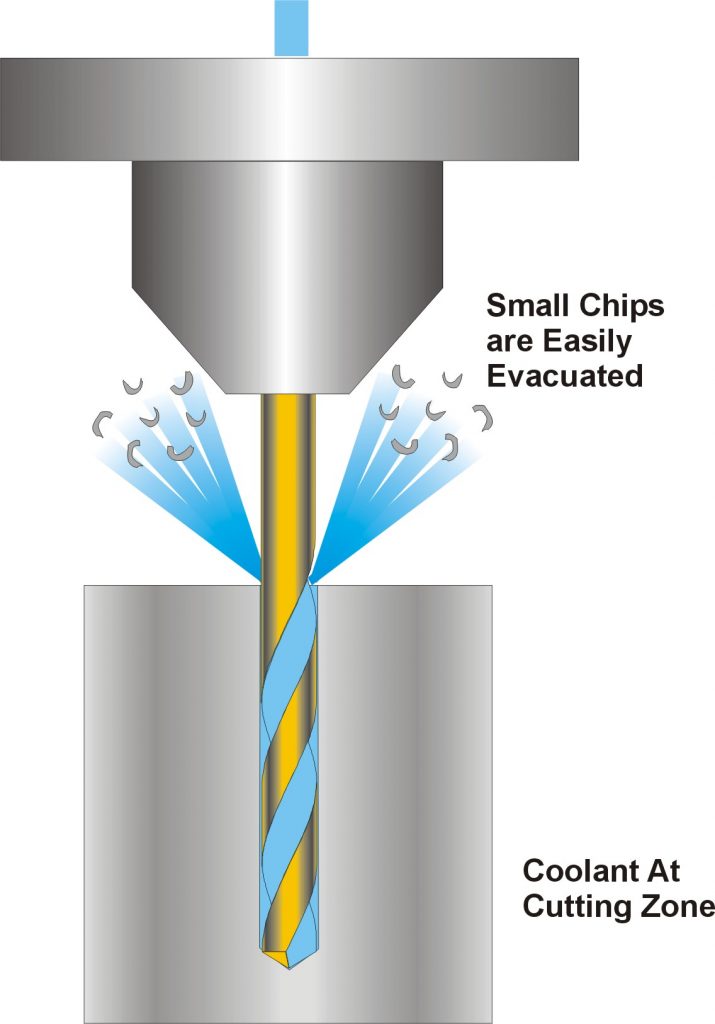

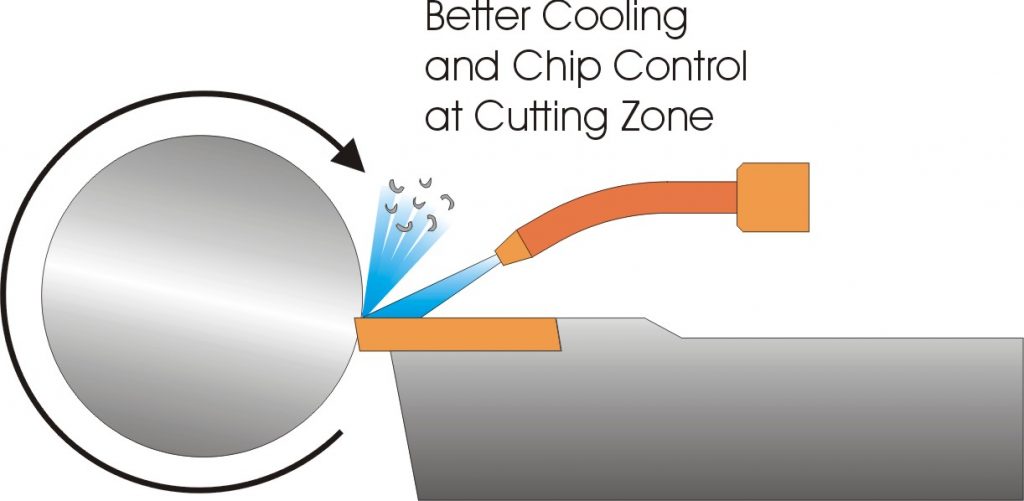

One technology that has reduced machine cycle times ‘leaps and bounds’ is High Pressure Coolant Systems (HPCS). In some cases, machining times have been reduced by 30%. This is primarily due to a dramatic increase in cooling at the cutting zone along with better chip evacuation. This is illustrated in the diagram on the right. Other benefits of using high pressure coolant systems include better surface finishes, increased tool life, and improved consistency.

Drilling

Flood Coolant

High Pressure Coolant

Benefits To Turning

Rough Turning:

Heat and Chip Control

Finish Turning:

Chip Control

Boring:

Heat and Chip Evacuation

Part-off:

Heat and Chip Control

Drilling:

Heat Control and Chip Evacuation

Tapping:

Heat Control and Chip Evacuation

High Pressure Coolant

The LATHAM High Pressure Coolant Systems are built with extreme high quality craftsmanship and are designed to last. LATHAM systems contain high quality, high pressure coolant pumps, heavy duty sheet metal enclosures, superior pleated cartridge filters, reliable electrical components and with our exclusive sound reduction system, the LATHAM system is significantly more quiet than the competition.

Choose the LATHAM High Pressure Coolant System that best suits your needs from the variety of models outlined in our catalog. For more information call (888) 422-7267 or visit our website at www.lathamproducts.com